Clinical study by Princeton Lab shows the regimen removes

95% of build-up

from scalp and hair.

The Proof - Princeton-Led Clinical Trial

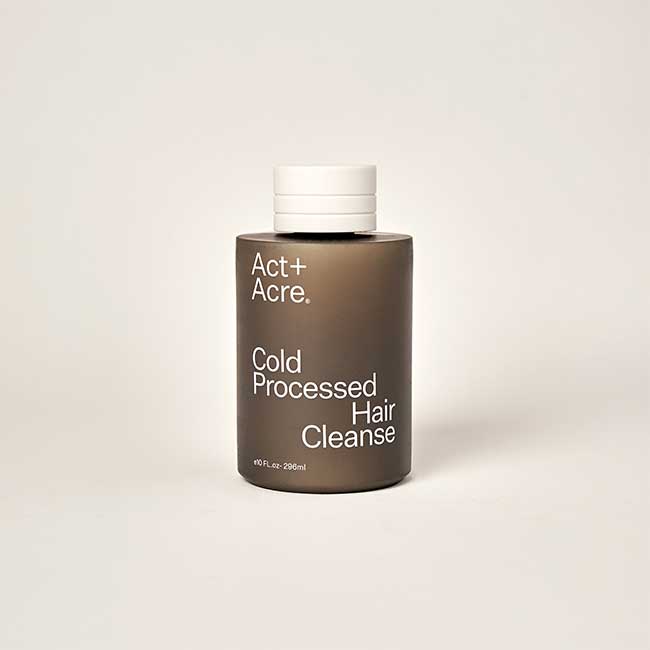

We put our three-step Cold Processed® system (Scalp Detox, Hair Cleanse, and Hair Conditioner) to the test to demonstrate the upheld integrity of our ingredients. Two leading scientists from the Princeton Research Education Service conducted a test on hair tresses of various weights, lengths, and widths using ATR-FTIR Spectroscopic technology.

Method of Study

The tresses were standardized with 0.15ml of a 15% Sodium Laureth Sulfate (SLES) solution, massaged, rinsed for 30 seconds and allowed to air dry at 60% relative humidity. 0.5g of sebum was then applied to the hair tresses to mimic greasy and dirty hair. The tresses were massaged for 30 seconds on both sides for even distribution of the sebum along the hair fibers and allowed to air dry at the same 60% relative humidity overnight.

Findings

Using ATR-FTIR spectroscopy to assess both 1) the initial sebum content (baseline) and 2) the hair after being treated with Sponsor (Act+Acre) products, the sebum amount present on the hair surface was significantly decreased. Overall, the product regimen performed consistently among all types of hair tresses treated, and the final reduction in sebum levels was higher than 95%.

Cold Processed® Method

ice cold water + high pressure

= 97% more Vitamin E

- Cold Processed®

- Traditional Heat Process (+160℉)

✝Extreme heat leads to evaporation of ingredients vital

minerals, reducing the level of nutrient content within the product.

✝Vitamin E is rich in antioxidant to repair damaged follicles, supports + protects hair follicle health against oxidative damage and premature hair thinning

The Past - Conventional Heat Processing

Over the past few decades, the haircare industry has become increasingly complex. Conventional hair products now contain up to tens or even hundreds of ingredients, and the list grows longer as makers continue to prioritize short-term performance over the long-term wellness of consumers and the planet.

While the industry favors a conventional heating process to mix products in a cost-effective manner, it can take up to five hours to achieve a homogenous mixture at temperatures exceeding 300°F. This sustained exposure to high heat not only has a material environmental impact, but can also significantly degrade the efficacy of naturally ingredients and introduce potential toxicological risks. For example, commonly used surfactants such as sodium lauryl sulfate and/or sodium laureth sulfate can interact and/or combine with other ingredients at elevated temperatures to form nitrosamines, which are known human carcinogens and can lead to human kidney and respiratory damage over time.

The Future - Cold Processed® Method

Determined to challenge the status quo, we partnered with leading scientists to adapt biochemical engineering technology into a new, innovative manufacturing process for hair products. Our patented Cold Processed(R) method uses hyperbaric chambers, ice cold water, and 1,200 pounds of pressure to combine our plant-based ingredients. By ensuring the internal temperature of the hyperbaric chamber never exceeds an ambient level of 68°F, the original ingredients remain fresh and highly potent. The absence of heat mitigates the loss of molecule compounds that would otherwise be released by the added energy. Further steps are then taken to reduce energy consumption, such as reducing the propeller speed to 200rpm when the temperature of a mixture approaches a given threshold relative to the ambient level.

The result is a nutrient-rich formula that easily absorbs into your hair and scalp for optimal health. With consistent usage, we’ve seen a significant improvement in both scalp health and overall hair wellness—leading to stronger, more resilient hair health. In 2018 the US Patent and Trademarks Office granted Act+Acre patent protection for our Cold Processed® method, which means we can continue to develop these products as both innovators and industry leaders.

Cold Processed® method uses...

Hyperbaric Chamber

consumes 90% less energy than

the traditional heat process

Hyperbaric Chamber

Hyperbaric chamber is an application of a pressure vessel to test the integrity of components and equipments subjected to high pressure. The chamber comprises of several main parts such as a shell, heads, instrumentation attachments, threaded fasteners and support. The design approach adopted is the "design by formula" method.

This is good for the earth

- Our packaging is fully recyclable

- Our products are environmentally friendly and held to the EU's clean standard

- We use 90% less energy during our production process

- Our partners subscribe to sustainable business practices and equal wages

- Our products are made locally in the USA

Ingredients

Each ingredient comes straight from its source across Asia, Africa, and the Americas. We partner with farms and labs that subscribe to sustainable business practices and equal wages to all parties, from the farmers who handpick each botanical ingredient, to the factory workers who extract the essences, to the scientists who develop the formulations. We think you deserve to know what you’re putting on your scalp and hair. All ingredients can be found on each product page. If you have more ingredient-specific questions, just shoot our team an email at hello@actandacre.com.

Eco-Friendly Production

By eliminating heat, our Cold Processed® Method consumes 90% less energy than conventional heat manufacturing. We’ve also partnered with a leading energy solution company to implement community-scale projects that reduce greenhouse gas emissions, strengthen businesses, and contribute to progress around the world. Our products are produced locally in the United States.

Packaging

Our bottles are made of PETG and PET, two of the most recyclable forms of plastic. We work closely with our manufacturing facility to ensure that these materials are directly tied to upcycling efforts to reduce plastic waste. Every piece of printed material, including the box your products arrive in, are produced from second-life, recycled materials and responsibly sourced from a managed recycling facility. As of January 2020, we are officially Carbon Neutral.

The 30-Day

Scalp Detox

132 men and women tried the scalp detox challenge for four weeks.

Check out the scalp restoration timeline for their results.

What is the 30-Day Scalp Detox?

[50% of Americans suffer from scalp issues.]

We challenged men and women with a range of issues, including dry scalp, flakes, dry itch, and sensitivity to use only Act+Acre products for 30 days.

Watch the video to see what happened.